Although you probably have your firm favourite Resene colours, have you ever wondered how the paint itself is actually made? Come with us as we visit the laboratory where the magic happens – the Resene manufacturing facility in Naenae. Here meet two clever scientists, Hamid and Zoe, who show us exactly how they make a batch of waterborne paint.

What’s the difference between waterborne and solventborne paint you may ask? Only a few decades ago most paint jobs were completed using solventborne paint, but as waterborne technology has improved, there has been a huge shift to waterborne paints.

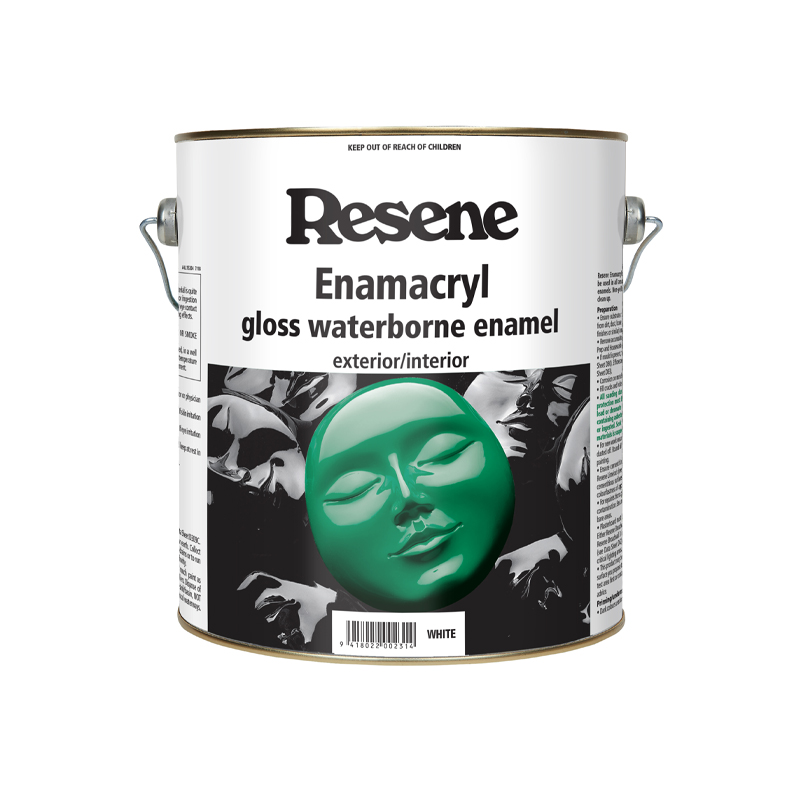

Resene made ground-breaking progress in 1996 by launching their first waterborne enamels – Resene Lustacryl semi-gloss waterborne enamel and Resene Enamacryl gloss waterborne enamel, which offer tough, durable, enamel-like finishes with all the benefits of waterborne paints, like being non–yellowing, low odour and easy to clean up in water.

In a major breakthrough for the industry, these new generation products are suitable for everything from broadwall areas through to wet areas, trim and joinery inside and out. Recognising the trend towards lower sheen finishes on interior broadwall areas, Resene then created Resene SpaceCote Low Sheen waterborne enamel and Resene SpaceCote Flat washable wall and ceiling.

Lab work

Getting back to the science at hand – at its core, paint is a material that is applied as a liquid and dries by a variety of chemical processes to a solid. While the exact formulas and ingredient ratios are Resene trade secrets, paint typically consists of pigment, resin, solvent and additives.

“Making the waterborne paint is a two–step process,” explains Hamid as he gets to work. “The first step consists of incorporating some special ingredients called pigments into the water.”

While it might look like a simple process, “the incorporation of these ingredients in the water is not an easy job, because we have huge scientific background and experience, we can do it in a perfect way here,” he says.

Pigments are one of the most important ingredients in the paint as they’re responsible for opacity and colour. These need to be dispersed into the water, but slowly, implores Hamid. As he slowly adds the powders, he increases the sheer speed of the mixer to create the perfected consistency. “When we get this doughnut shape, it means that we are doing our job perfectly.”

Once all the powders have been added to the solution, it needs to sit for at least 15 minutes and after that, stage one of making waterborne paint – which is known in the paint game as the ‘dispersion process’ – is done. Hamid is left with a product known as the mill-base.